Stages of Window Production

uPVC Windows

The journey of uPVC window production at WindoStyle begins with a series of precise stages that ensure a strong, insulated product with a long lifespan. High-quality uPVC materials are first selected, then accurately cut using the latest cutting machines to ensure dimensional accuracy. Next, internal reinforcement bundles made of galvanized steel are prepared, which are essential for the window’s strength and resistance to wind and pressure.

- Profiles: Made from uPVC (unplasticized polyvinyl chloride), making them lightweight and rust-resistant.

- Glass: Single or double, often double-glazed, enhancing insulation.

- Reinforcements: Galvanized steel is used to strengthen and support the profile, increasing its durability.

Below are the manufacturing steps of uPVC windows and the machinery used:

Stages of uPVC Window Manufacturing

Stage (5)

Stage (6)

Stage (7)

Stage (8)

Stage (9)

Stage (10)

Stage (11)

Stage (12)

Stage (1): Cutting uPVC Profiles

The first step in uPVC window manufacturing is cutting the profiles, whether (frame – sash – transom – buckler – mesh sash) in the production of facades, doors, and uPVC windows, and therefore:

- We pay close attention to the precise measurements of the wall opening, on which uPVC windows, doors, and uPVC facades are installed.

- We share with the client the most suitable design drawings according to the wall opening size to maximize its benefit. There are also flexible options based on each client’s needs and budget.

- The accuracy of profile corner cutting has a very important impact on achieving high-quality uPVC windows and doors with excellent performance.

- The saw blade and operating platform must be kept dry and clean, otherwise it will affect the subsequent processing performance in uPVC window manufacturing when cutting the uPVC window frame.

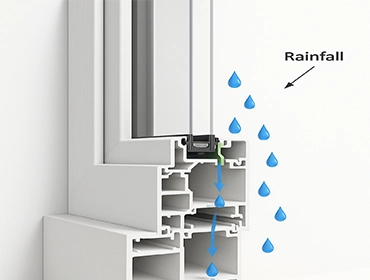

Stage (2): Drilling Drainage Holes

We always ensure that our uPVC windows and doors perform well against rainwater or any water exposure. This makes us at Windostyle:

- We provide the necessary drainage openings to allow water to exit, while also creating a pressure-balancing hole on the profiles to ensure smooth water flow according to the location and function of each hole.

- The holes include internal drainage openings, internal pressure-balancing openings, and external drainage openings.

Where and how many holes should we create?

We must clearly know where to make the water drainage openings and the balance openings, and how many of them there should be, during the manufacturing process. uPVC Windows

Before we begin, we must know the areas where holes should not be made.

>>> Some key points we need to pay attention to

- Do not connect the drainage hole and the internal reinforcement steel in the uPVC window. If this happens, rainwater will seep into the main cavity, causing the steel to rust.

- The drainage holes should be located at the lowest point of the cavity, as this helps prevent water accumulation inside the profiles.

- There should be a gap between the internal drainage hole and the external drainage hole.

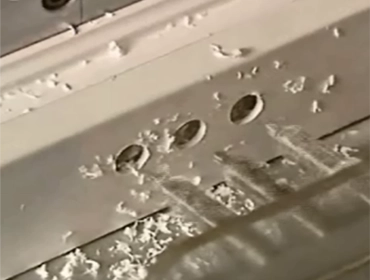

Stage (3): Drilling Accessory Holes

We need to create some accessory mounting holes on the profiles during the uPVC window manufacturing process. These holes are usually made on the window profiles.

1- How to create an accessory mounting hole?

There are several methods to create these holes, but we usually use a drilling machine or a standard manufacturing device.

2- What type of accessory mounting hole should we create?

We usually create the lock hole, handle hole, and the special cylinder hole in door manufacturing. These holes can be made using the template on the_

We must also drill the hole in the correct position and ensure it is smooth and free of burrs, which is essential for accurate accessory installation.

Stage (4): Reinforcement Steel Installation

Function of Reinforcement Steel

- First, improving rigidity and strength Windows and doors made of UPVC

- Second, to prevent deformation and, moreover, to make accessory installation more secure.

Technical Requirements for Reinforcement Steel

- The surface of the iron is treated with an anti-corrosion coating or zinc to prevent rusting.

The size and shape of the reinforcement steel.

- The reinforcing steel is installed inside the main chamber of the profiles during the manufacturing of a uPVC window or a uPVC door.

- The clearance between the main cavity of the reinforcement steel and the UPVC profiles is 0.51 mm.

- This gap makes the installation process easier to restore after the window is compressed.

- The reinforcement steel must be shaped according to the profile cavity and type.

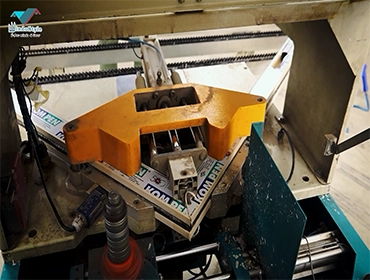

Stage (5): uPVC Profile Welding

Do not use nails to assemble the corners of UPVC windows and doors, instead, the ends are thermally welded using a special welding machine under clamp pressure at the same temperature used during profile extrusion, ensuring the welded ends are uniform and form a single piece.

This is the opposite for windows made of aluminum or wood, where the window corners are assembled using parts joined with nails, which may be affected during installation or after use.

Stage (6): Cleaning uPVC Profile Corners

After welding, the welded surface will have excess weld buildup in the manufacturing of UPVC windows or doors. To avoid affecting the function and appearance of the window, the corner needs to be cleaned.

For casement windows, excess weld buildup will affect the leak resistance between the sash frame and the window frame.

For sliding windows, excess weld buildup on the welded profile will affect the sliding of the sash panels.

We clean the visible excess weld on the frame and sash to preserve the aesthetic appearance, prevent leakage, and ensure ease of use for the related accessories.

The four sharp corners are cleaned to prevent stress during window assembly and installation, as well as to preserve aesthetics and avoid damage to the handles during opening and closing.

Additionally, all weld excesses that affect the appearance and the installation of accessories must be cleaned.

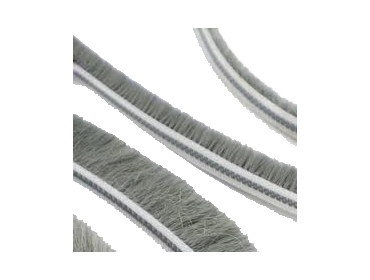

Stage (7): Installing Dust Sealing Sash

UPVC profile weatherstripping is usually installed in sliding UPVC doors and windows. It is a strip of felt used to prevent water and dust from entering.

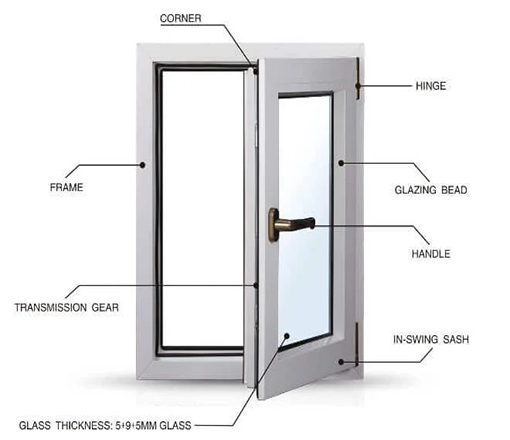

Stage (8): Installing Accessories

We select the hardware accessories according to the structure and design of the uPVC window, whether it is sliding, hinged, or any other type of uPVC windows.

Windostyle, as a UPVC window manufacturer that prioritizes quality, considers the use of high-quality UPVC window accessories extremely important.

UPVC Window Accessories:

- UPVC Window Hinges are used to ensure smooth cooperation between the frame and sash, and to support the weight of the window sash as well as wind pressure. UPVC window hinges are made from UPVC material.

- UPVC Window Handles are primarily used to open and close UPVC windows and doors. They are selected according to the design of the UPVC window.

- UPVC Window Espagnolettes are used to lock the window or door at multiple locking points with the use of handles. They are selected according to the design and dimensions of the UPVC window.

- UPVC Window Rollers are used to move the window or door sash along the frame track. The roller surface must be smooth and free of any defects.

- UPVC Window Dust Seals are used in sliding windows on the frame or door between the moving sashes to block dust and prevent it from entering.

Stage (9): Glass Installation

يتم تثبيت لينات الزجاج في الضلف التي تحمل الزجاج قبل إدخال الزجاج نفسه. لينات الزجاج عبارة عن قطع من البلاستيك الصلب بطول 3 بوصات (7.6 سم). ندخل قطعة واحدة في الجزء العلوي والسفلي من كل من الضلف الزجاجية التي جاءت مع شباك uPVC. سيضمن ذلك أن الألواح الزجاجية تتناسب بشكل صحيح مع الألواح أثناء تثبيتها.

Available Glass: Single glass, double glass, and insulated glass.

Depending on the gas inside the insulated glass, it is classified as either standard glass or double glass filled with inert gas.

Stage (10): Product Inspection and Review

We need to ensure the quality of our production in manufacturing UPVC doors and windows, as we are a distinguished supplier of UPVC windows.

Final Product Inspection in UPVC Window Manufacturing

After assembling the windows, before leaving the factory, some samples must be taken according to the different types and dimensions of the windows.

There are also several other elements that must be inspected before leaving the factory.

1. Corner weld strength.

2. Installation of reinforcement steel.

3. Installation of accessories.

4. Opening and closing force of the lock and handle.

5. Opening and closing force of the sash.

6. Inspect the glass installation and ensure its integrity.

7. External appearance of the UPVC window.

Stage (11): Window Transport and Delivery

- Doors and windows must be placed in well-ventilated areas, protected from rain, and kept dry and level.

- In manufacturing UPVC doors and windows Outdoor storage is not permitted, and they must not be allowed to come into contact with corrosive materials.

- All windows must also be placed vertically according to the installation direction, with the vertical angle not less than 70 degrees. Flat stacking directly on the ground is not allowed.

- In the manufacturing of windows and doors made of UPVC, the windows must be loaded and unloaded gently.

- It is very important to arrange the doors properly in the cart when loading windows and doors.

- We maintain stability to prevent movement and vibration and to avoid contact between the accessories and the glass.

- We use a soft material to separate the windows and place them vertically in an organized manner.

Stage (12): uPVC Window Installation

The installation stage is one of the most important phases in the production of UPVC doors and windows, as correct installation depends on the unit's performance quality. Therefore, we always ensure to have a team of the best and most skilled installation technicians in the field of UPVC doors and windows.

1 – The frame is injected with foam from the outside before installation in the wall opening to ensure that all gaps between the frame and the wall are filled, guaranteeing insulation quality and strength.

2 – The frame is placed in its designated opening and then leveled using a spirit level to achieve maximum balance, after which the frame is fixed to the wall using the special installation screws.

3 – The foam is trimmed and any resulting debris is removed, then silicone is applied to ensure proper insulation.

4 – The sashes and unit accessories are installed, the protective stickers on the profiles are removed, the unit is cleaned, and then delivered to the client.

uPVC WindowsEasy to UseCost-EffectiveMultiple OptionsAesthetically PleasingMaintenance-FreeFrom WindoStyle

We offer you the expertise gained over twenty years in the manufacturing of uPVC doors and windows. This experience allows us to provide you with tried, tested, and certified products. We offer a complete package – pre-sale consultations, a wide range of products, on-site measurements, installation, and after-sales service.

Asked Questions

If you’re looking for windows and doors that provide excellent sound insulation, WindoStyle is here for you. We are the preferred brand for purchasing energy-efficient and soundproof windows and doors in Egypt. Our building assemblies are designed with multi-chamber profiles, tight seals, welded corners, double-glazed insulated glass, and more, all contributing to superior sound insulation.

The cost of new soundproof windows and doors may vary depending on the configuration you choose. At WindoStyle, you have glass options as well as choices like sliding doors, hinged windows, fixed windows, and more. If you are planning to get new windows and doors and want to know the cost, contact us. One of our expert team members will assist you with all your inquiries.

Applying sealants and using waterproof materials for doors and windows are crucial ways to protect them from rainwater leakage. Thanks to the innovative design offered by WindoStyle for doors and windows, you can effectively prevent rainwater penetration and protect against damage.

WindoStyle windows and doors require minimal maintenance. They are resistant to decay and dust and do not warp. These doors withstand harsh weather and storms, provide insulation against rainwater, and are unaffected by heat or sunlight. They will remain in excellent condition, looking like new for years to come. All that is required is routine cleaning to remove dirt and dust from the surfaces and channels, as these doors and windows are designed for lifetime performance.

WindoStyle doors and windows require very little maintenance. Routinely cleaning dirt and dust from the surfaces and channels will keep WindoStyle doors and windows in excellent condition, making them look like new year after year. They are resistant to decay and corrosion and maintain their shape. Designed for lifetime performance, they require only minimal cost and effort to preserve their appearance.

If you notice that your WindoStyle doors and windows are not performing as expected, or if you experience any resistance or difficulty in operating them, it is time for a maintenance check. In such cases, we recommend contacting WindoStyle customer service to schedule a service and maintenance inspection to ensure your doors and windows are functioning properly.

UPVC windows and doors are renowned for their strong resistance, even against heavy rain and wind. WindoStyle UPVC windows and doors are designed with innovative design and technology, making them the ideal solution to prevent rainwater from entering and to keep your home safe.

WindoStyle UPVC doors and windows have been tested for reliability and durability against adverse weather conditions. Designed with unique solutions such as steel reinforcements and multiple locking points, WindoStyle UPVC doors and windows provide strong protection against wind, storms, and rainwater leakage, keeping your home safe and secure.

WindoStyle windows and doors require minimal maintenance. They are precisely manufactured to ensure proper sealing with no gaps and are corrosion-resistant. They withstand decay, dust, and storms without warping. All that is needed is routine cleaning to remove dirt and dust from the surfaces and channels, as these doors and windows are designed for lifetime performance.

WindoStyle windows and doors are made from highly durable materials, providing long-lasting life and high performance. Moreover, WindoStyle windows and doors require minimal maintenance and remain in excellent condition, looking like new for years to come.

Yes, you can install insect screens from WindoStyle to protect your home from insects, pests, and mosquitoes. These screens are easy to open and close, allowing fresh air to flow in while keeping insects out.

Energy efficiency is one of the key factors when choosing uPVC doors and windows for your home. They offer benefits such as lower electricity bills, improved door and window performance, reduced maintenance, and more. WindoStyle uPVC doors and windows are designed with double-glazed insulated glass and multiple locking points, making these building assemblies energy-efficient and secure.